Rubber Ship Seal Spare Parts Replacement for Boat Ship Shaft

Rubber Ship Seal Spare Parts Replacement for Boat Ship Shaft

The rubber seal for the ship’s tail seal is used for the rotary seal of the dry ship’s tail shaft. It has the dual functions of sealing oil and sealing water. It is generally composed of sealing elements and clamping and positioning components, and is an important component of the marine power plant. Due to the harsh working environment and installation under the waterline outside the ship, maintenance is very difficult and the requirements for the sealing device are high. There are five main types of structural forms.

(1) Oil ring type: It consists of two oil ring and three oil plate.

(2) Skeleton oil seal type: It is a kind of contact type lip seal with axial oil resistance. It is generally made up of 3-4 oil seals, two of which are water-blocking. Two oil-blocking.

(3) Floating seal: generally consists of three rubber skeleton oil seals and anti-vibration bushings, which can overcome the shortcomings of the skeleton oil seal on the radial runout adaptability of the shaft seal.

(4) Face seal: It is a sealing device composed of a combination of rubber seal and metal parts, and is commonly used in medium-sized ships.

(5) Xinpulex seal: its sealing element consists of three Xinpex rubber seals with a clamping spring on the lip. This seal [1] has good shaft followability, wide adaptability and good sealing effect. ,long lasting.

Product range of IKSONIC ship seals: Rubber seal, Inflatable, Spring seal, bearing, Single-end, double-end, non-standard design type: Kettle seal series offer: Discount click consultation advantage: single end, double end.

Marine seals, professional seal manufacturers, low loss, easy assembly and disassembly, German imported seals, marine seals, long service life, low power consumption, no need for frequent maintenance, reliable mechanical seal, small leakage, various models complete.

The axle of the ship is called the tail shaft in the industry. One end of the tail shaft is connected to the propeller, and the other end is connected to the gear box or the coupling is connected to the engine. The tail shaft of the large ship is mounted on two bearings. One is called the tail bearing, which is the hull. The part in contact with the water. The other is called the front bearing, which is connected to the nacelle. The front and rear bearings are the tail shaft compartment, which is basically closed. But there is no air pressure or anything.

The sealing of the hull is achieved by a sealing ring installed beside the front and rear bearings. The sealing ring is a closed rubber ring and is placed on the shaft. Generally, the front and rear bearings have several sealing rings. The two sealing rings are used between the two. Oil-filled, this oil is a tank from a certain height. It is a gravity oil tank, which can balance the pressure of the water. And the oil can lubricate the seal ring and reduce the wear speed of the rubber ring.

In fact, the industry is called tail seal and front seal.

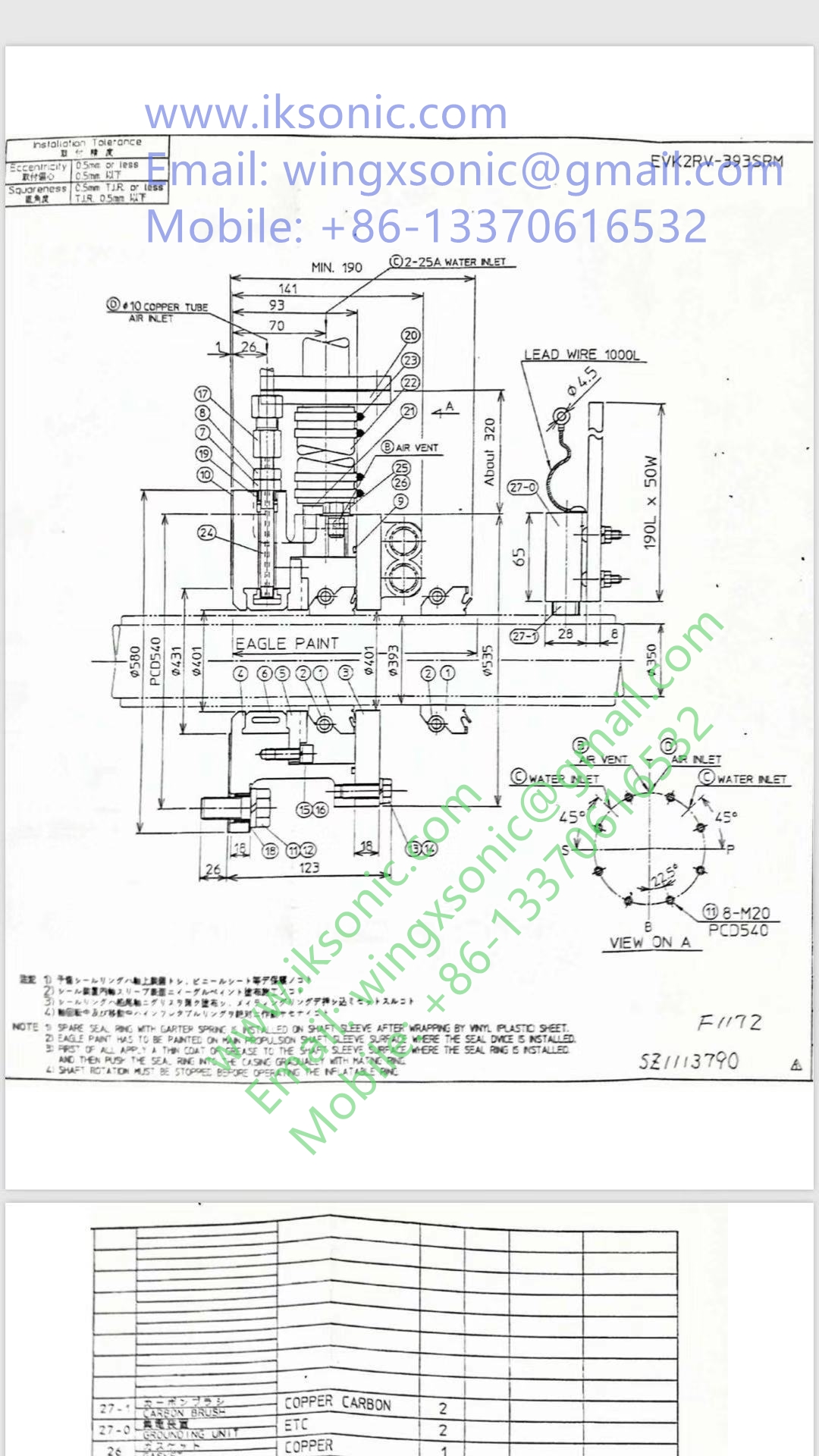

Rubber Ship Seal Replacement Boat Ship Shaft water seal drawing for ship seal

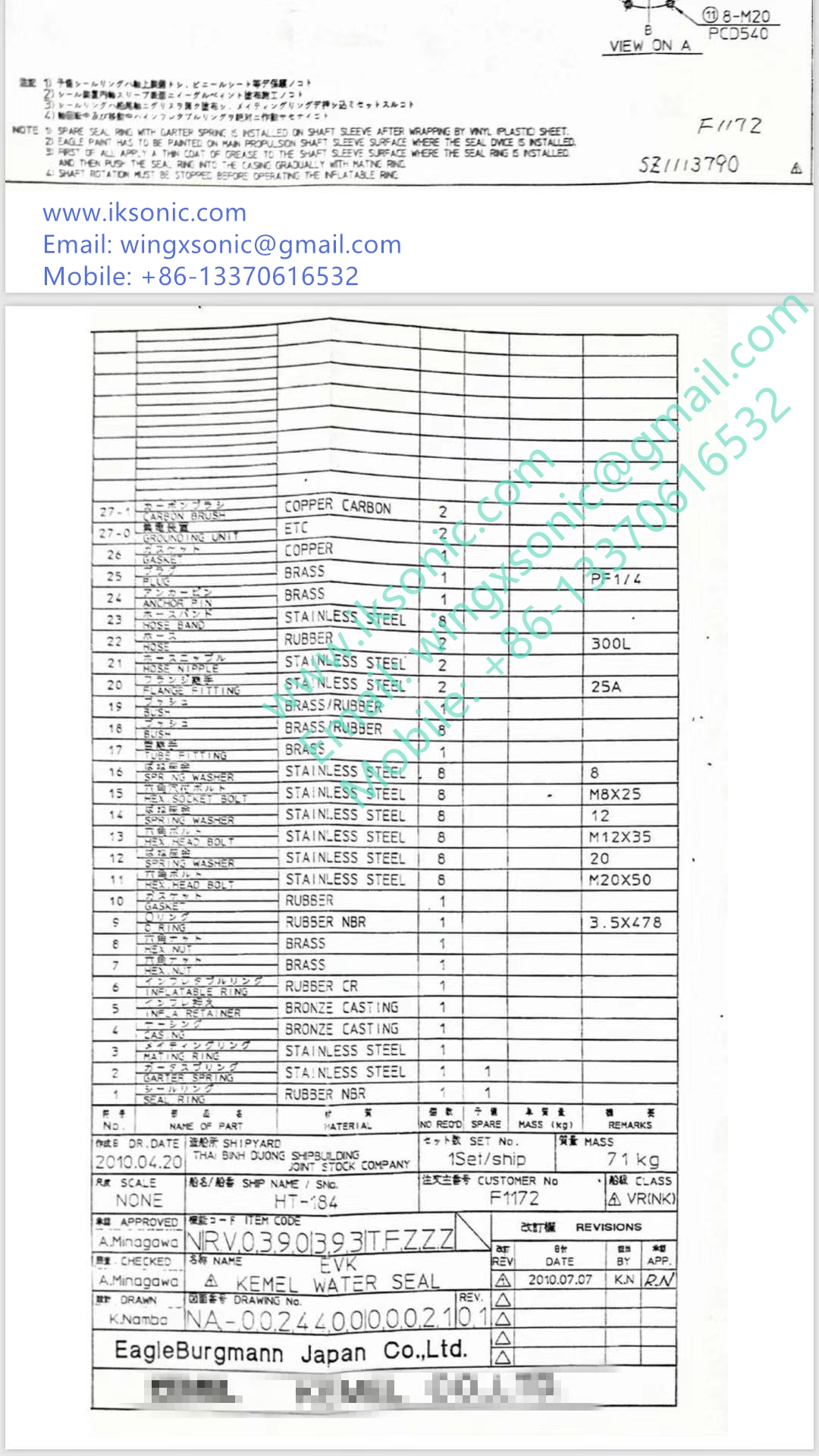

Part number Rubber Ship Seal Replacement Boat Ship Shaft inflatable seal drawing

If the tail seal leaks, the water pressure enters between the two seal rings, causing the oil level of the gravity oil tank to rise, and the monitoring alarm system will alarm, and the crew will know that the tail seal has a problem.

The front seal is connected to the nacelle, and there is little water inflow problem. However, if the front seal ring is damaged, the seal oil leaks out, causing the oil level of the gravity oil tank to drop, and the monitoring system alarms, the crew knows that the front seal has a problem.