PCTFE (Polychlorotrifluoroethylene) is currently the best known low temperature polymer material. Because PCTFE is an indispensable sealing material for aerospace military liquid fuels, it has long been blocked by foreign countries. Therefore, few private companies in China have mastered processing technology. .

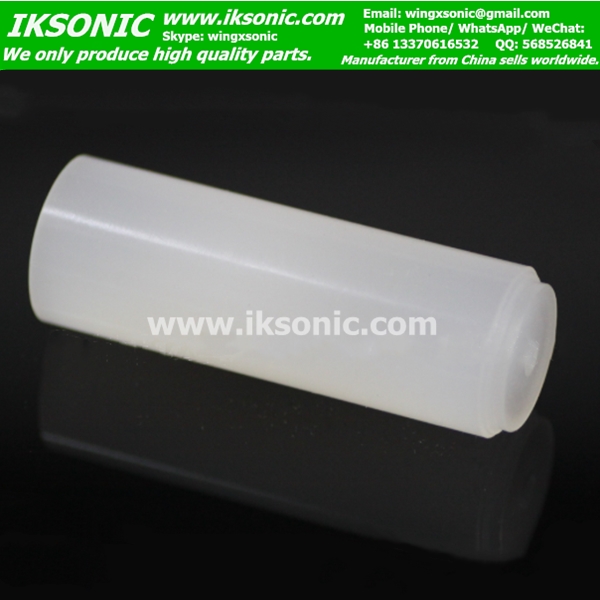

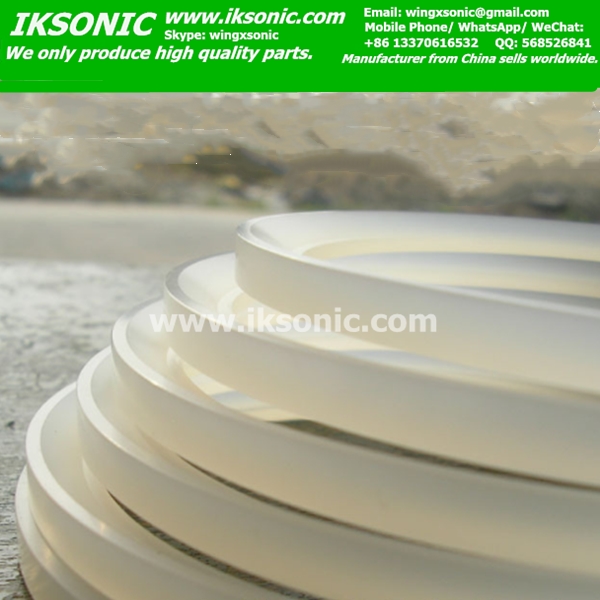

Our company has jointly developed a number of national invention patents by cooperating with a number of research institutes. The company has applied for a number of national invention patents. Our company is one of the few private companies in China that can truly master the PCTFE compression molding process. IKSONIC could produce various PCTFE tube and PCTFE rod materials. we not only produce ultra-low temperature working conditions seals, but also provide customers with integrated sealing solutions for ultra-low temperature equipment development.

PCTFE Product introduction:

A polymer of chlorotrifluoroethylene. English abbreviation PCTFE. The structure has a melting temperature of 213 ° C, has excellent chemical stability, insulation and weather resistance, can be used for a long time at -196 ~ 125 ° C, mechanical strength and hardness is better than polytetrafluoroethylene, the film has better transparency and Lower air permeability. PCTFE is a crystalline polymer having a melting point of 425 F and a density of 2.13 g/cc (g/cc).

It is a product of a chlorotrifluoroethylene free radical initiated polymerization with a linear backbone that primarily repeats a CF(cl)-CF unit.

PCTFE is a crystalline polymer having a melting point of 425 F and a density of 2.13 g/cc (g/cc).

PCTFE is inert to most active chemicals at room temperature, and can be dissolved by a few solvents above 212T, or by some solvents, especially chlorinated solvents. PCTFE has excellent gas barrier properties, and its membrane product has the lowest water vapor permeability of all transparent plastic films. Its electrical properties are similar to those of other perfluoropolymers, but the dielectric constant (2.3-2. Knife and loss factor are slightly higher, especially at high frequencies. It can make thick (1/8 inch) optically transparent Pieces.

Processing and application:

Although PCTFE can be melt processed, it is difficult to process due to high melt viscosity and degradation tendency of the processed product.

PCTFE resin can be made into pellets for molding and extrusion. The film thickness is from 0.001 to 0.010 inches and can also be made into rods and tubes. Polychlorotrifluoroethylene (referred to as F3) resin spray molding method, belonging to chemical equipment anti-corrosion technology. It is a mixture of polychlorotrifluoroethylene resin, phenolic resin and graphite powder as a binder for the surface of polychlorotrifluoroethylene plastics and metal equipment. Prior to spraying the F3 top layer, a bond transition layer is first applied to the surface of the metal substrate. The method has the advantages of simple process and convenient operation, is not limited by the shape and size of the device, and has the advantages of widely sprayed equipment, widely used medium and high strength, and can be widely used for petrochemical, pharmaceutical, pesticide and the like with corrosive operation convenience. It is not limited by the shape and size of the equipment. It has the advantages of wide spray equipment, high use medium and high strength. It can be widely used in corrosive chemical industries such as petroleum, chemical, pharmaceutical and pesticide.

Application areas:

Corrosion-resistant parts on chemical equipment such as pipes, valves, valve seats, high-pressure sealing packings, gears, bearings, diaphragms, gaskets, linings and coatings for reaction pots, storage tanks, ventilators, centrifuges, etc. , high-frequency cable, coil insulation, etc.; moisture-proof, anti-stick coating.