Plug-in type Inflatable rubber seal strip Water circulation pump nuclear power plant

Plug-in type Inflatable rubber seals strip Water circulation pump nuclear power plant

IKSONIC Rubber Plastics Products Group Co., Ltd. is specialized in rubber sealing products, special rubber products, special rubber material , for development and production as high-tech enterprises.

Seawater circulating pump means nuclear power plant needs a rubber seal and gas seals who bring other media. Inflatable rubber seals strip has been widely used in similar large-scale equipment.

Currently used in nuclear power plants abroad seawater circulating pump with a inflatable rubber seal products mainly include two structural forms: a hollow closed structure, the other is flat on both ends of the open structure, heating the adhesive stick high temperature use. Closed structure with seal products in actual use will need to lift the whole pump shaft and the drive motor, high cost, and replacement back loading period, the power generating unit can only be reduced to half the normal case, can cause extreme large material losses. The open seal structure during installation and replacement of the bonding process requires extremely harsh, a little mistake, we must tear down the re-bonding. In recent years, with China increasing number of nuclear power plants, water circulation pump that need large nuclear power equipment is more reliable and secure seal.

To solve the problem of seawater circulating pump seal, IKSONIC Rubber Plastics Products Group Co., Ltd. developed a new type of plug-in type inflatable rubber seal strip.

click & send an product inquiry to IKSONIC team.

Email: [email protected]

WhatsApp/Mobile/WeChat: +86-13370616532 , +86-15315489052

WeChat: taishanfu

Skype ID: wingxsonic

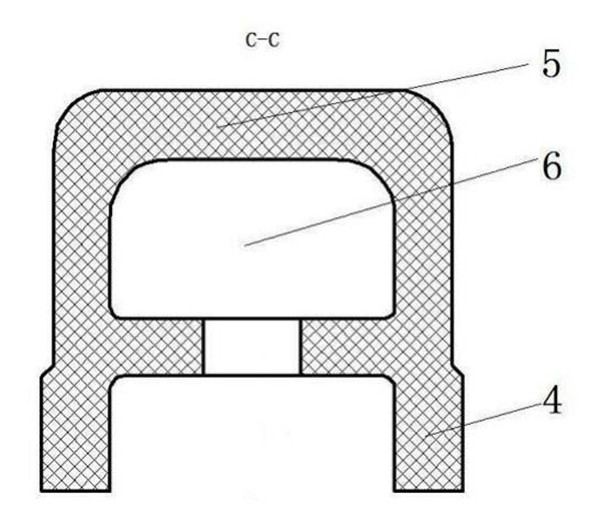

The plug-in type inflated water-resistant sealing tape select properties and excellent adhesion properties of rubber as the main material, through a special fit, the material has excellent resistance to compression deformation capacity and resilience. In the case of a pneumatic sealing tape can hold pressure water pump shaft seal at the bottom; sealing tape after deflation can quickly return to its original position, to ensure the sealing surface of the shaft there is a certain gap, to prevent the shaft seal surface friction even sudden death phenomenon.

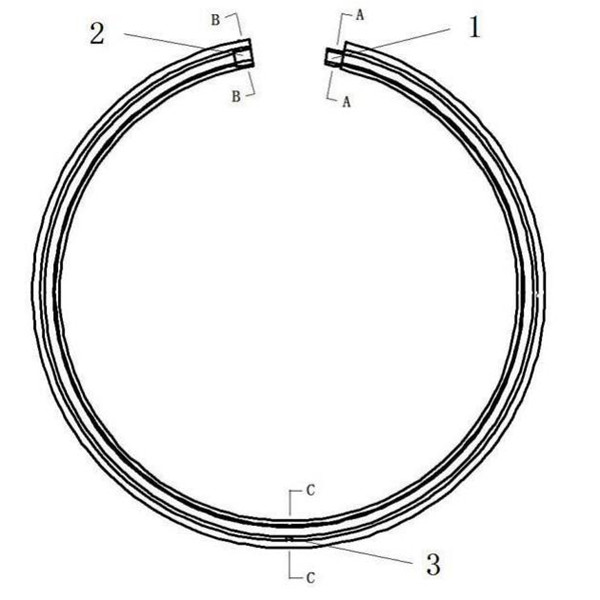

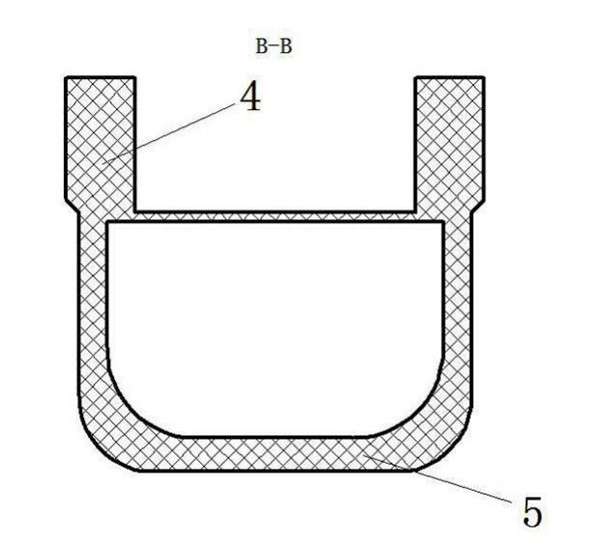

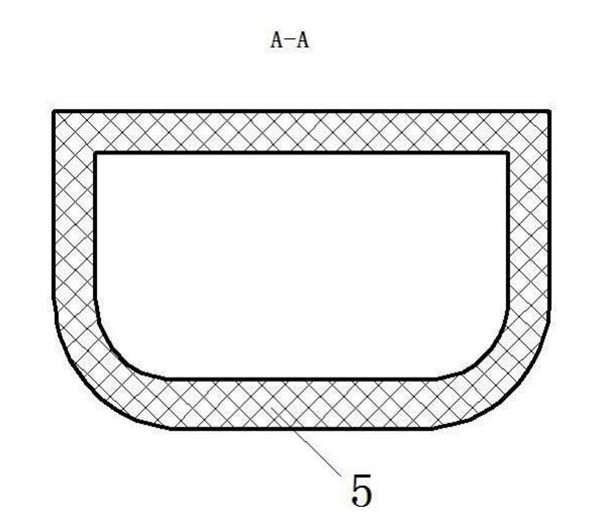

When installing the sealing strip to the male port 1 (as shown) is inserted into the female port 2 by adhesive bonding as a whole closed ring, which is D-shaped cross-sectional structure. Wherein the sealing surface 5 inflated snapping the shaft; fixing surface 4 by the gland sealing tape fixed to the shaft; when the shaft is rotated, the sealing surface of the shaft 5 with a certain gap, to ensure that the bottom of the water pressure can upwelling to reduce friction and heat between the shaft and packing; when the shaft stops rotating, compressed air through the airway pump cover, seal gas nozzle into the interior belt, so that after the expansion of the shaft and close fit to prevent Chung bottom pressure water, corrosion pump gear box and other parts. At 0.2MPa of air pressure, can be sealed with a seal swell 10 to 15m head of water pressure, pressure 30min, allowed leakage, drip and other micro-leakage, but does not allow continuous pressure water gushed; in the 0.3 MPa under atmospheric conditions, the expansion can be sealed with the seal 20 to 25m head of water pressure, pressure 30 mins, allowed leakage, drip and other micro-leakage, but does not allow continuous pouring water pressure. Ends were sealed with the male and female port 1 to port 2 when installing the sealing tape is wrapped around a shaft, yin and yang port plugged together with adhesives for bonding, sealing tape after bonding sufficient to suppress, at 0.2 Mpa under pressure conditions, the pressure drop within 30 mins it does not exceed 0.02 Mpa.

[sw_latest_products products=”9″ cats=”202″]