Extrude solid rubber o ring cord manufacturer in china

Viton FKM O Ring Cord and Silicone Rubber O Ring Cord Seal Strip.

click & send an product inquiry to IKSONIC team.

Email: [email protected]

WhatsApp/Mobile/WeChat: +86-13370616532 , +86-15315489052

WeChat: taishanfu

Skype ID: wingxsonic

- Description

- Contact Us

Description

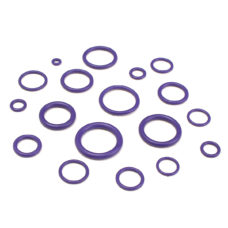

Welcome to IKSONIC. We are one of the leading manufacturers of extruded solid rubber O-ring cord in China. Our main products include extruded solid rubber O-ring cords of various sizes and specifications, which can be widely used in fields such as automobiles, machinery, electronics, aerospace, etc. We focus on the quality and performance of our products, using high-quality rubber raw materials and advanced production processes to ensure that every product meets customer requirements.

Material

* NBR

* Silicone

* Viton

* EPDM

Specification

Viton O-Ring Cord Silicone Rubber Seal Strip are commonly used in high temperature sealing applications. Many other colours, sizes and grades can also be supplied.Many other silicone extruded profiles are available.

Dimensions: Diameter 1mm-80mm .

Shape: O-type, round cord.

Color: usually black, other colors can be offered, we can make it as per your requirements.

Hardness: As per your request.

Extrude solid rubber o ring cord manufacturer in china

PRODUCT ADVANTAGES

• Can be used both for hydraulic and pneumatic system

• Can be used for static applications

• Wide compound range

• Wide range of dimensions

• Easy installation and removal

• Excellent resistance to heat, water, ozone, ageing and weathering

• Good cold flexibilities.

We offer Viton O-Ring Cord Silicone Rubber Seal Strip to your exact required size.

Applications of : Viton O-Ring Cord Silicone Rubber Seal Strip used for High temperature sealing, door seals, oven seals, packaging and food processing machinery.

Also available: Other sizes, colors and shore hardness available upon request.

Length (mtrs):Various depending on diameter.

Working condition:

It`s important that keep the clean of working medium. Oil aging or pollution could make the components fail, accelerate the aging and abrasion of oil seal. Moreover the dirt could lead seal failure. Therefore, workers must be check the quality and cleanliness of oil regularly. Sealing parts are burn out by high temperature which caused by residual air compressed in oil of cylinder. In order to avoid it, in the initial operation of hydraulic system, exhaust air disposal is needed, hydraulic cylinder also should be work several minutes firstly under low pressure and slow running. Work normally after confirming that all of the air have be removed.

If you have any questions or products request, please leave message or call us.

Email: [email protected]

WhatsApp/Mobile/WeChat: +86-13370616532 , +86-15315489052

WeChat: taishanfu

Skype ID: wingxsonic

Scan the QR code above, add me on WeChat.