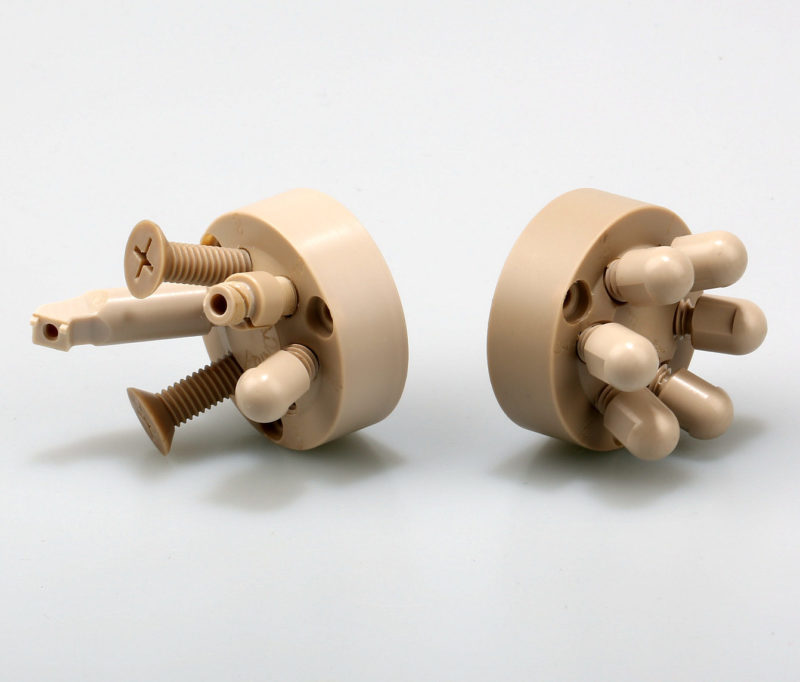

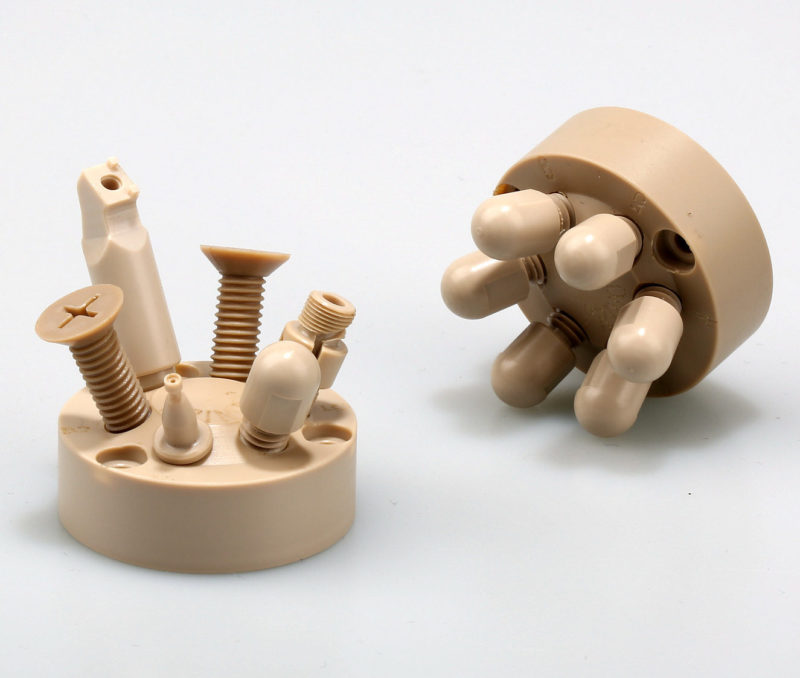

PEEK CNC five-axis precision machining manufacturers custom special engineering plastics parts

click & send an product inquiry to IKSONIC team.

Email: [email protected]

WhatsApp/Mobile/WeChat: +86-13370616532 , +86-15315489052

WeChat: taishanfu

Skype ID: wingxsonic

- Description

- Contact Us

Description

PEEK CNC five-axis precision machining manufacturers for custom special engineering plastics parts

- Machining type: CNC machining center

- Constant temperature workshop special engineering plastics PEEK CNC five-axis precision machining manufacturers custom

- Precision: finishing

- Processing material: PEEK

- The maximum diameter: 400 (mm)

- The maximum length: 300 (mm)

- tolerance: 0.01mm

- Surface roughness: 1.6

- Proofing cycle: 1-3 days

- Processing cycle: 4-7 days

- Annual remaining processing capacity: 1500 (pieces)

- Maximum annual processing capacity: 15000 (pieces)

- equipment: Constant temperature workshop, five-axis linkage processing, online inspection, 3D printing, etc.

- Accuracy range: High-precision and high-strength accuracy can reach ±0.01m (one wire)

Key points of PEEK CNC five-axis precision machining processing:

The molding process of peek materials includes injection molding, extrusion molding, blow molding, pressing, mechanical processing and other methods. Among them, mechanical processing is quite different from metal general engineering plastics in terms of thermal expansion, heat dissipation performance, elasticity, and wear resistance. If you don’t pay enough attention to it for PEEK CNC five-axis precision machining, improper operation will cause explosions and even damage processing equipment.

Causes of material bursting during PEEK CNC five-axis precision machining processing:

- ①As the stress of the blank itself is not completely eliminated, bursting occurs during processing.

- ②Blasting occurs when using too large a knife to eat during processing.

- ③Use a larger drill to drill directly, it is easy to squeeze and burst due to the large cutting force.

- ④During deep hole processing, the drill bit was not repeatedly retracted to remove chips, and the chips were not fully discharged, causing cracking due to extrusion.

- ⑤ Insufficient cooling. When the drilling is insufficiently cooled, the cutting heat and cutting force generated are too high, and it will also burst.

- ⑥If the feed speed is too fast, it will increase the internal stress of the PEEK bar and cause bursting.

- ⑦Because the PEEK material is wear-resistant, the cutting edge of the drill bit wears out quickly when drilling. At this time, if the drill bit is not sharpened in time, the hard drilling will also cause explosion.

If you have any questions or products request, please leave message or call us.

Email: [email protected]

WhatsApp/Mobile/WeChat: +86-13370616532 , +86-15315489052

WeChat: taishanfu

Skype ID: wingxsonic

Scan the QR code above, add me on WeChat.