Turnery Polyurethane Seal Turning PU Seal No Mold Tools

Manufacturer of Turning PU Seal for high quality.

click & send an product inquiry to IKSONIC team.

Email: [email protected]

WhatsApp/Mobile/WeChat: +86-13370616532 , +86-15315489052

WeChat: taishanfu

Skype ID: wingxsonic

- Description

- Contact Us

Description

IKSONIC can manufacture the Turnery Polyurethane Seals without any Mold Tools.

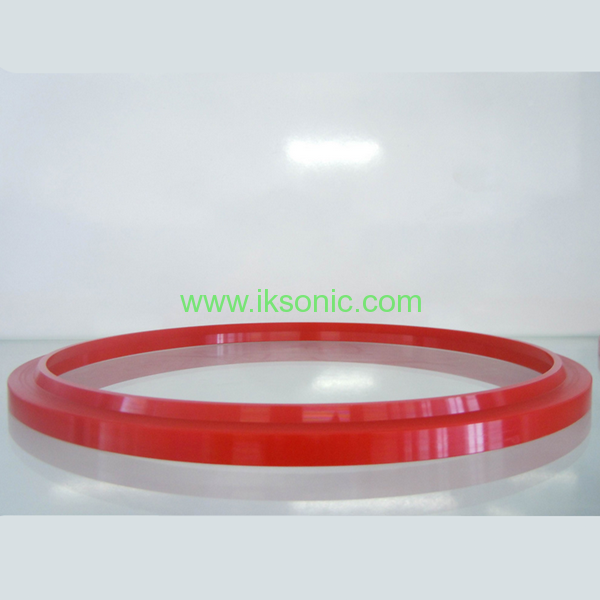

Turning PU Seal

Turning PU Seal

Specification:

Name: no mold tools, turning polyurethane sealing

Brand: OEM

Working Pressure: 45MPa

Working speed: 0.5m / s

Working temperature: -30 ℃ ~ 110 ℃

Working medium: hydraulic oil.

Turning polyurethane seal no mold has the following characteristics:

1, no standard and non-standard limits any cross-sectional shape can be turning, such as: various sizes dust ring, shaft U-ring, U-ring hole, shaped pieces.

2, Turning PU Seal diameters ranging from 8 mm to 2.5 m between can be processed without a mold.

3, imported seals and special machine tool processing, high precision products to meet the equipment requirements of different working conditions.

4, fast delivery. Dispatch same day delivery, within 1 meter specification two days of delivery, 1 meter to 2.5 meters specification three days of delivery. Shorten lead times and large equipment downtime.

5, using high-quality imported raw materials to produce polyurethane products with water resistance, oil resistance, high tear strength, excellent physical properties and other characteristics.

Turning PU Seal and seal production technology differences:

Turning polyurethane seals are made of imported raw materials after heated liquid melt-casting blank barrel material, and then transmitted through the seals of various software programming data to a dedicated turning CNC machining equipment for processing seals, hydraulic seals, molded hydraulic seals: molded hydraulic seals by abrasive made of melted rubber or polyurethane filled after heating, the following deficiencies:

①, dense and poor, due to the lack of an open mold filling defective product is easy;

②, and theoretical material will vary depending on the temperature data environment, material batches, product size and so shrinkage rate deviation, is likely to cause the finished product tolerances, size is not easy to control and so on.

④, different cross-section, different sizes need to open special mold, cumbersome process, relatively long lead times.

IKSONIC can offer professional production of large-sized turning polyurethane sealing, Turning PU Seal within 2.5 m of various, and to undertake a variety of sealing engineering technology projects, to resolve various seal leakage problems, and to Provide a full sealing technology solutions.

If you have any questions or products request, please leave message or call us.

Email: [email protected]

WhatsApp/Mobile/WeChat: +86-13370616532 , +86-15315489052

WeChat: taishanfu

Skype ID: wingxsonic

Scan the QR code above, add me on WeChat.